3D Modeling & CAD

Founded in 1977, AIA Plastics, Inc is a plastic fabrication company specializing in CNC routing, vacuum forming, thermo forming, welding, fabrication and machining of all types of plastics. A.I.A. Plastics, Inc. has the capability and capacity to:

DWG and IGES are the preferred file types however, we can also use: PART, ASSEMBLY, DRAWING, DXF, ADOBE, LIB FEAT PART, FORM TOOL, TEMPLATE, ACIS, VDAFS, VRML, STL, UGII, CADKEY and IDF.

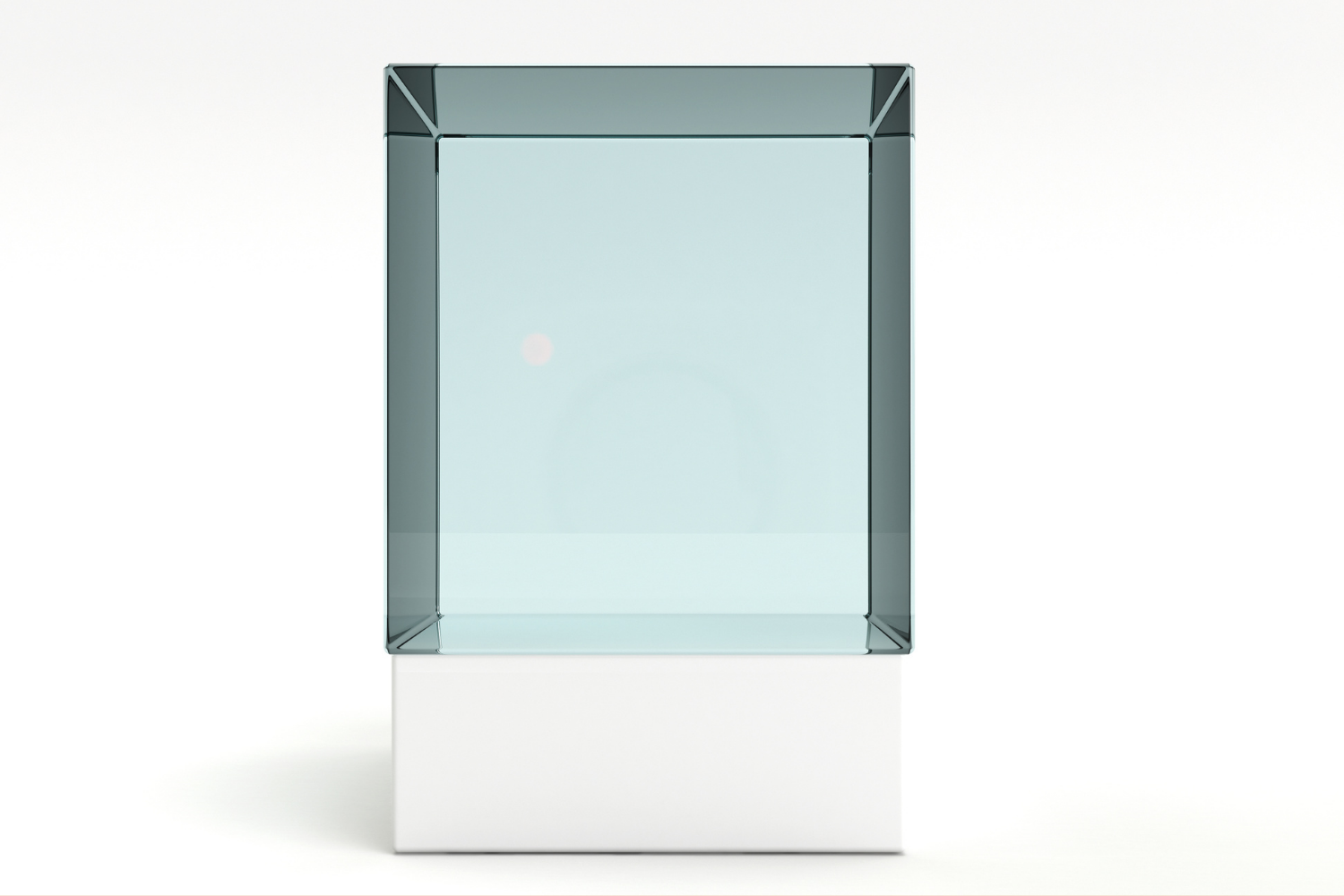

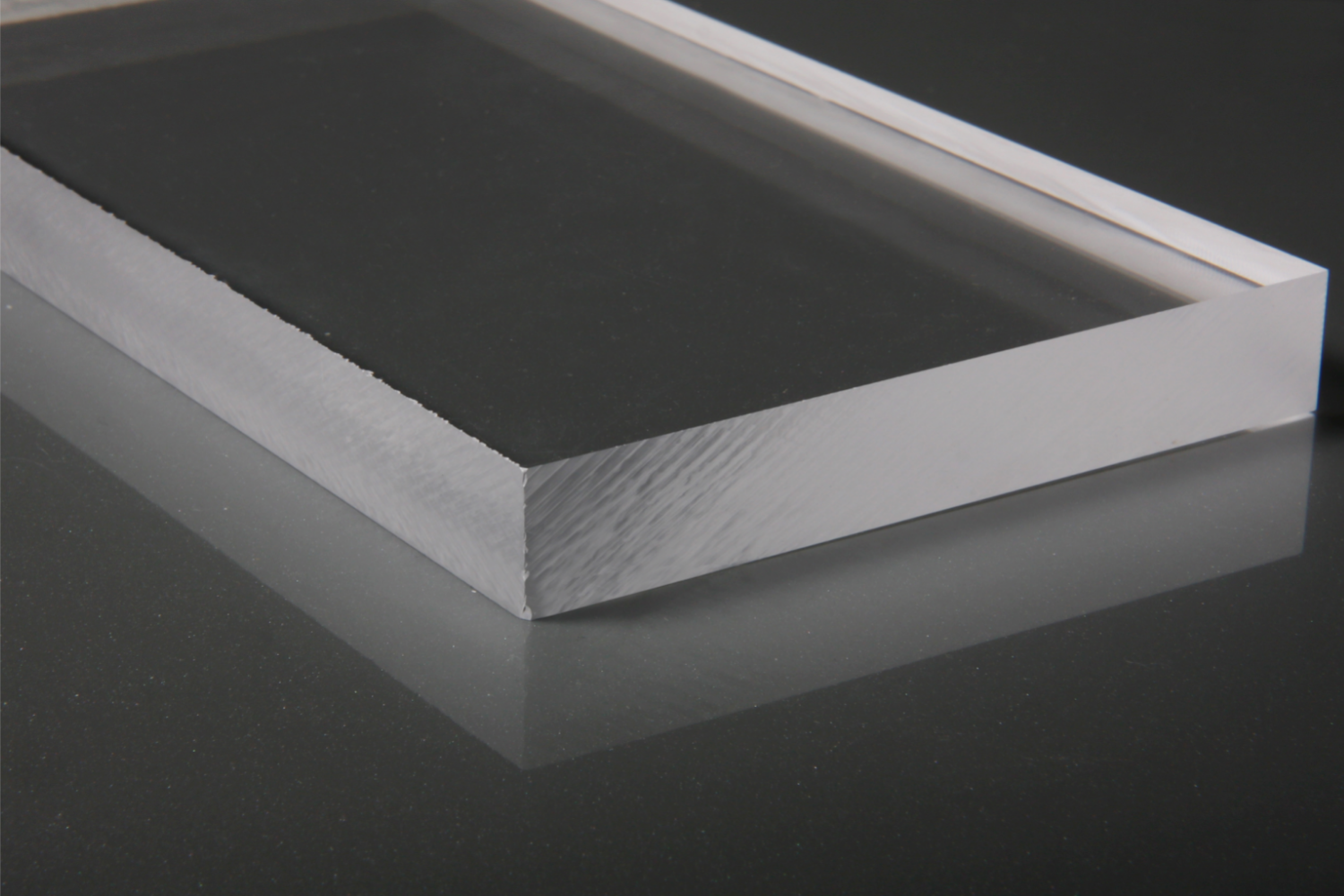

Acrylic Displays

AIA Plastics, Inc has been creating custom Acrylic displays for over 30 years. We provide displays to a wide range of customers such as: Museums, Convenience Stores, Retail Stores, Cosmetic Companies, Tobacco Companies and more.

Assembly

Gain from the extensive experience AIA has accrued over the last 30 years and let us guide you past the "bumps" in your project. We can work with you to help alleviate design and construction problems and can offer better and more cost effective ways to build your project.

Bending

Bending can be done in a variety of ways. Whether using a strip heater, heat gun or sheet metal brake, bending can be done on many different plastic materials. The maximum material thickness for bending is .500" without a "V" groove.

Bonding

Bonding plastics depends on the type of material you are using. Materials such as Acrylic, ABS, PVC, Polycarbonate and Styrene are easily chemically bonded with the correct solvents or cements. Some other plastics may require a different, more advanced method to bond them together.

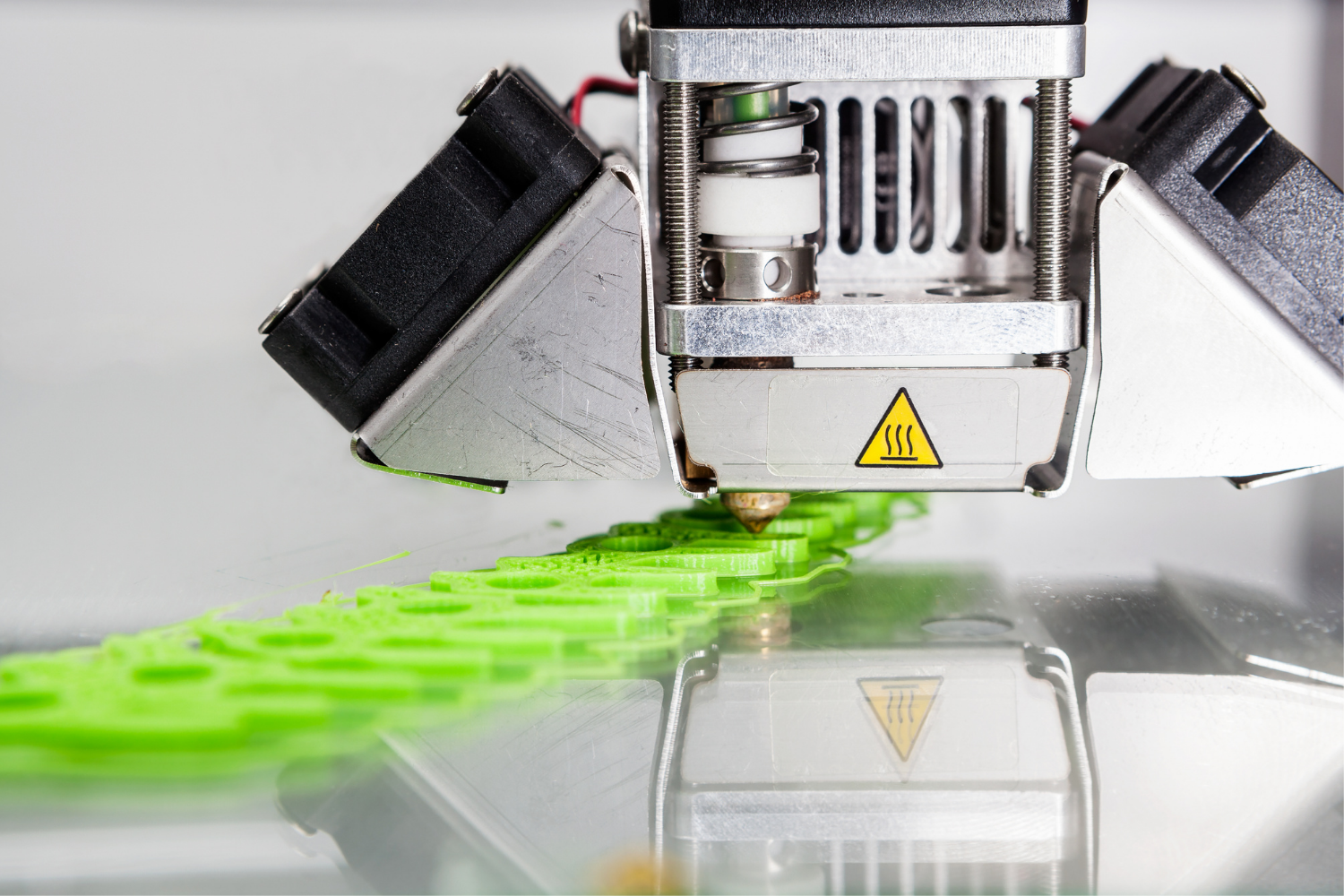

CNC-Routing

CNC (Computer Numerically Controlled) Routing creates a physical 2D or 3D model based on a computer generated file (nc). CNC Routing is ideal for certain applications (Landform, Profile Fabrication), is more cost effective and allows for several material options.

AIA Plastics Inc has three KOMO CNC routers, ranging from 60" x 96" – 60" x 120" in table size, with 10 head tool changers.

.png)

Cutting

Cutting with a table saw is standard in the industry. AIA Plastics, Inc also uses a Komo CNC router and computer operated horizontal panel saw for cutting.

Maximum thickness is 4" with no limit on length or width.

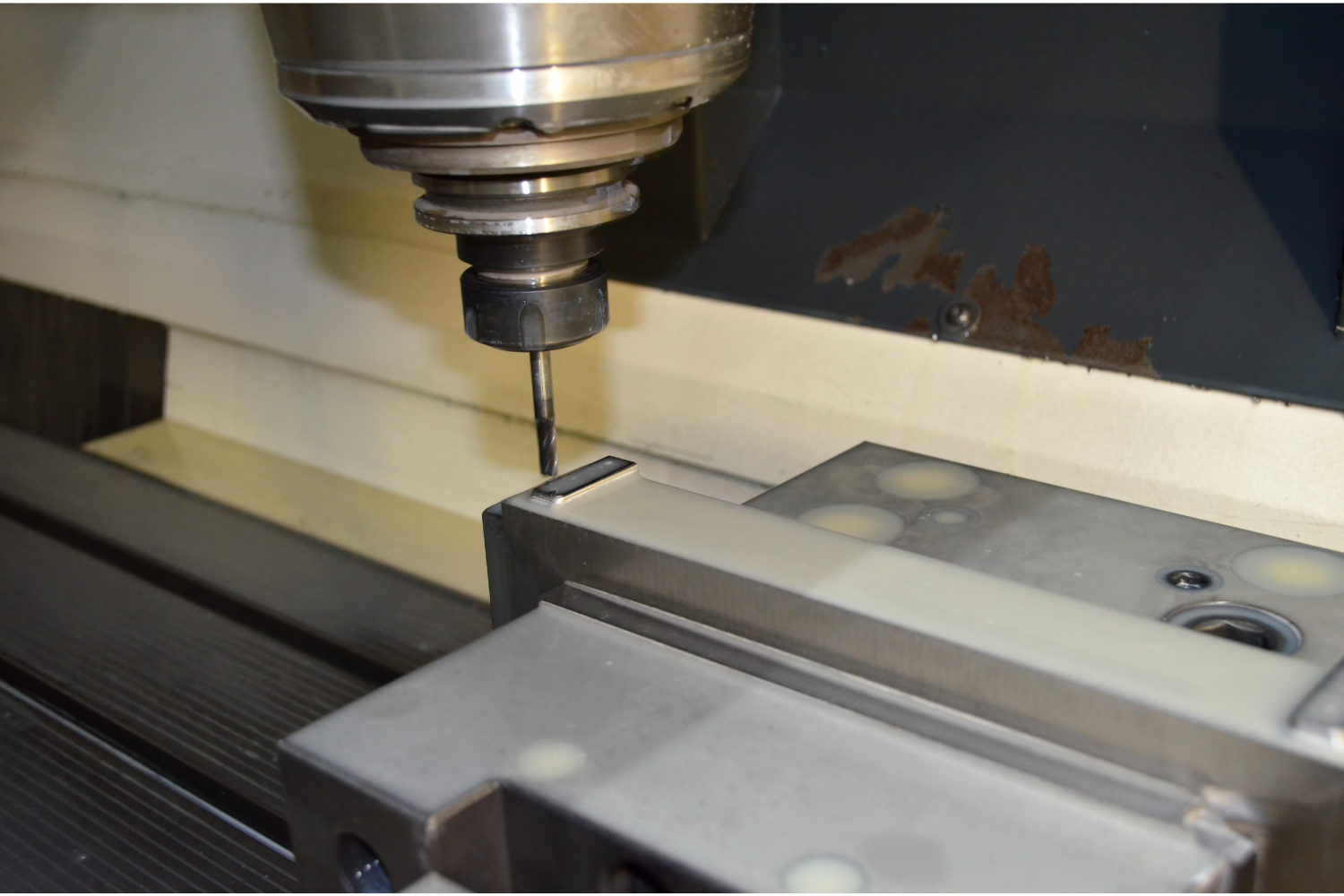

Drilling

Drilling holes can be done by using a Cordless/corded Electric Drill, a Drill Press or even the KOMO CNC Routers. Tapping a hole is also an available feature. No hole is too large or too small.

Light Lenses

Need a replacement Light Lens or a Diffuser? AIA Plastics, Inc manufactures custom Light Lenses and Diffusers for numerous lighting applications. We can provide Acrylic and Polycarbonate Lenses, Covers, Globes, Sconces, Domes and Bowls. Faux finishes are also available upon request.

Machining

AIA Plastics, Inc can take care of all of your custom machined plastic needs as well.

Plastic Fabrication

AIA Plastics, Inc can help you with all of your plastic fabrication needs from helping you create a concept or design to fabricating your finished part(s). We specialize in CNC Routing, Vacuum Forming, Thermo Forming, Plastic Welding, Quick Turn Fabrication and Large Production Run Fabrication.

Plastic fabrication can be achieved in many ways. The type of fabrication depends on the materials being used. Some materials can be bonded and others need to be welded or mechanically fastened.

Plastic Welding

AIA Plastics, Inc's plastic welders are Qualified by the American Welding Society (AWS). We can custom weld a variety of plastics into any shape or size.

Plastic Welding is a process of using hot air to heat the material in a sort of "soldering" process. Welding Rod, made from the same material, is then applied to the seam to "bond" the material together.

Hot Gas Welding

Hot gas welding, also known as hot air welding, is a plastic welding technique which is analogous to gas welding metals, though the specific techniques are different. A specially designed heat gun, called a hot air welder, produces a jet of hot air that softens both the parts to be joined and a plastic filler rod, all of which must be of the same material. Hot air/gas welding is a common fabrication technique for manufacturing smaller items such as chemical tanks, process equipment, clean room and mechanical assembles.

Extrusion Welding

Extrusion welding allows the application of bigger welds in a single weld pass. It is the preferred technique for joining thicker material. Welding rod is drawn into a miniature hand held plastic extruder, plasticized, and forced out of the extruder against the parts being joined, which are softened with a jet of hot air to allow bonding to take place.

Polishing

Polishing is done on acrylic parts to provide a "glass" like finish to the edges of parts. This process is accomplished by using a combination of hydrogen and oxygen to create a 2400 degree precision flame polishing the edge of the material. For acrylic thicker than .25", AIA Plastics also offers conventional rotary buffing.

Routing

Many types of routing are available at AIA Plastics, Inc including but not limited to flush routing, trim routing, veneer trimming and CNC routing. There is no limit to the size of part that can be routed with a hand router. The size limit on the Komo CNC router is 60" x 120".

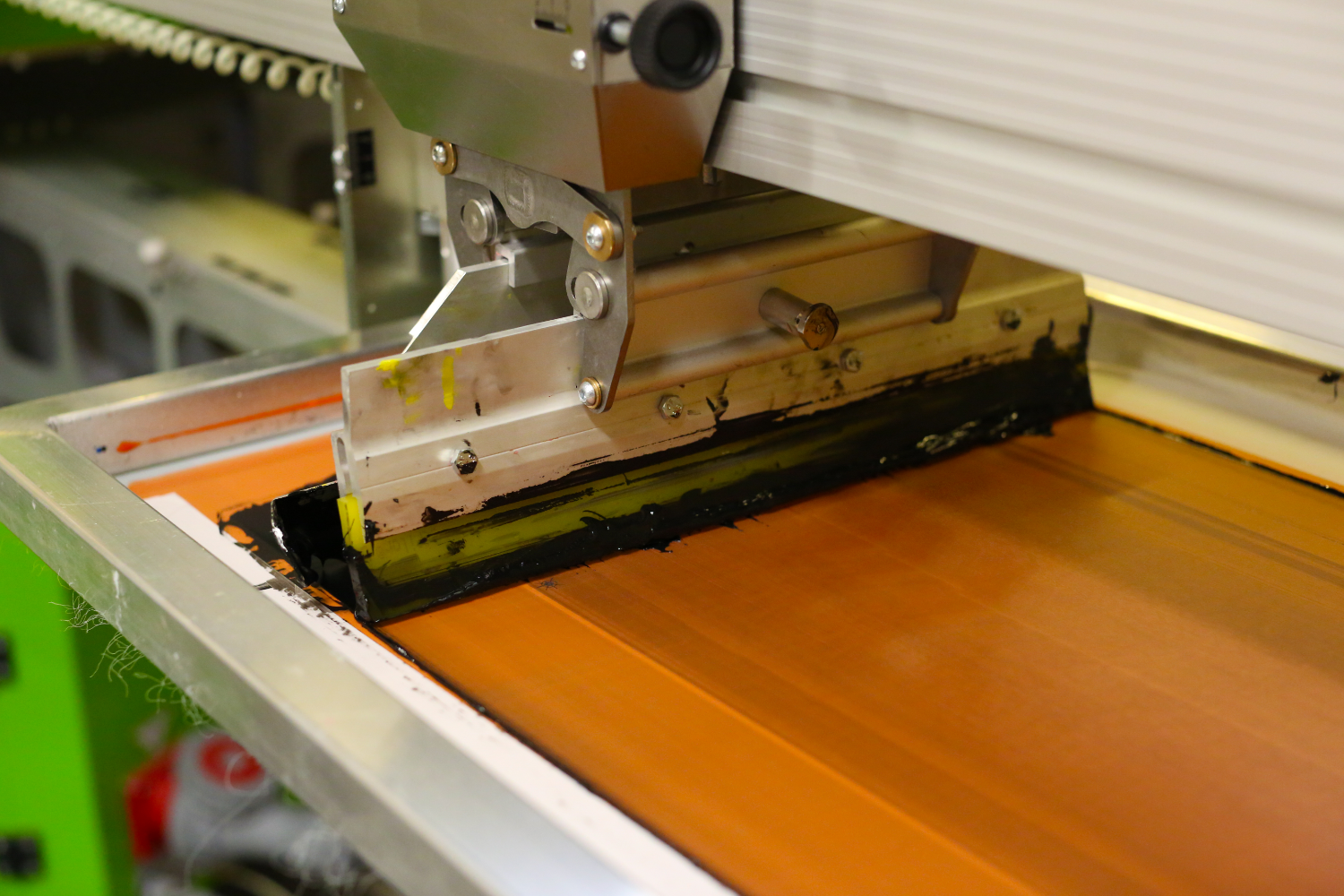

Silk Screening

Silk screening is available on many different materials including but not limited to acrylic, expanded pvc, styrene and more.

Thermo Forming

Thermo Forming also known as "drape forming" is a process of heating product in an oven and then laying the product over a form while hot. This allows us to form a wide array of radii and other shapes. The largest heating capacity available to AIA Plastics, Inc is 120" x 144".

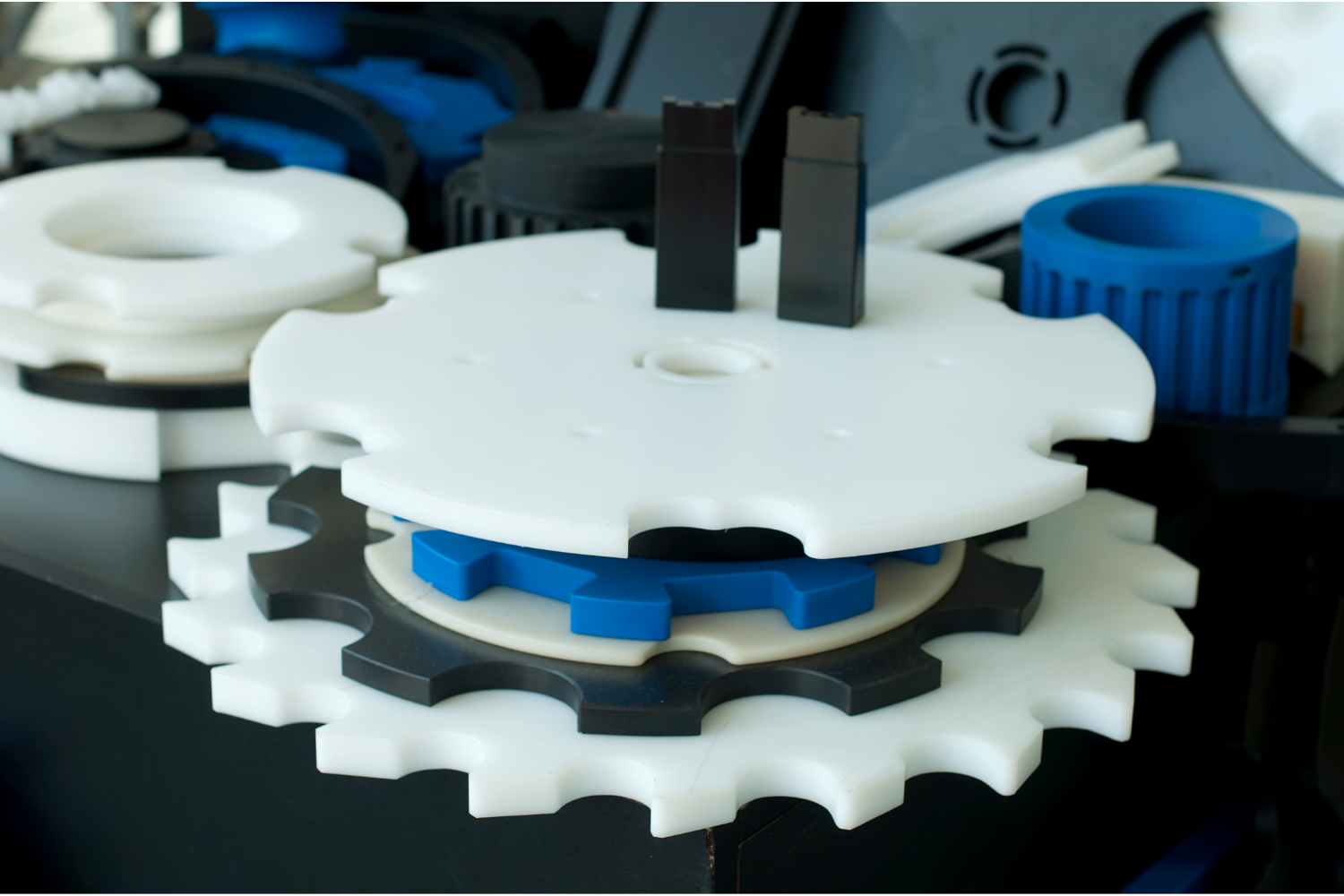

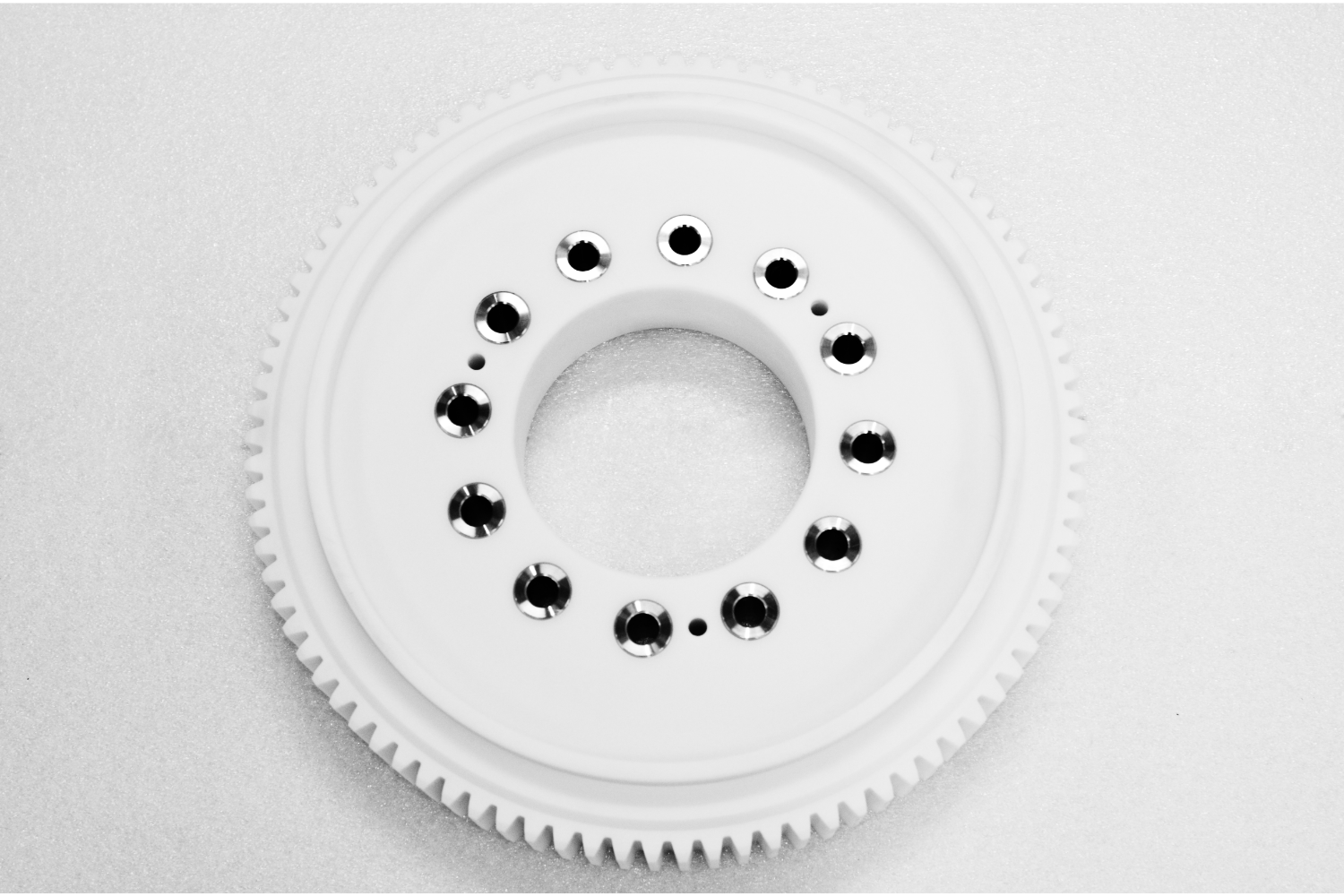

Wear Strips & Chain Guides

UHMW wear strips, chain guides, sprockets, belt guides and rollers all custom made by AIA Plastics, Inc to your exact specifications or we can even reverse engineer your part.

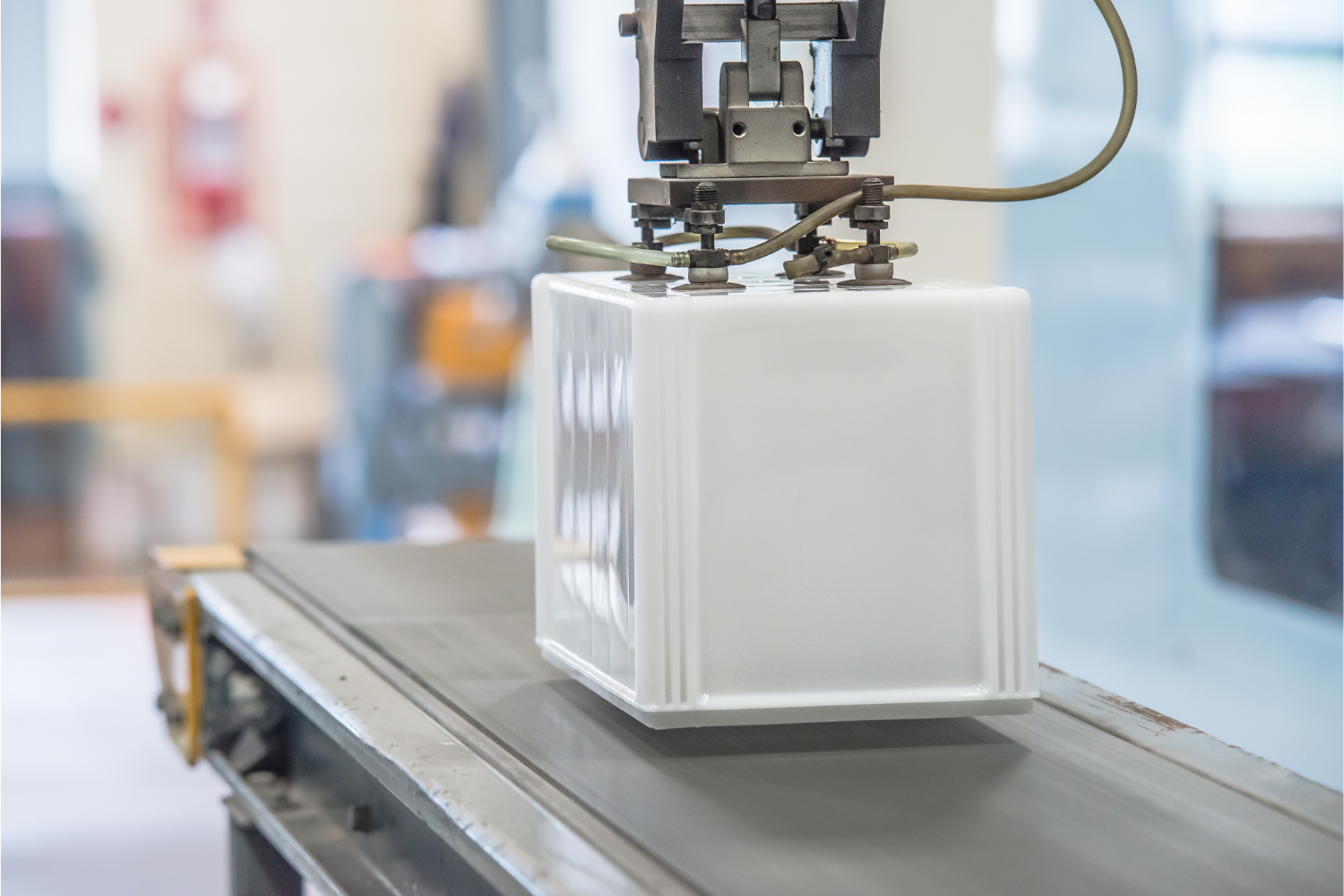

Vacuum Forming

Vacuum forming is a technique that is used to shape a variety of plastics. Doing this involves the use of an oven, platen and a vacuum source. Sizes of vacuum formed parts can vary, however, the largest part we can form is 120" X 144".